Specialized laser cutting and laser welding

Customized laser processing for every requirement

We are specialized in the field of laser cutting and laser welding. We have laser systems with different performance classes and properties to meet the individual requirements of our customers. Whether laser cutting, laser welding or laser deposition welding – we are your reliable partner on site.

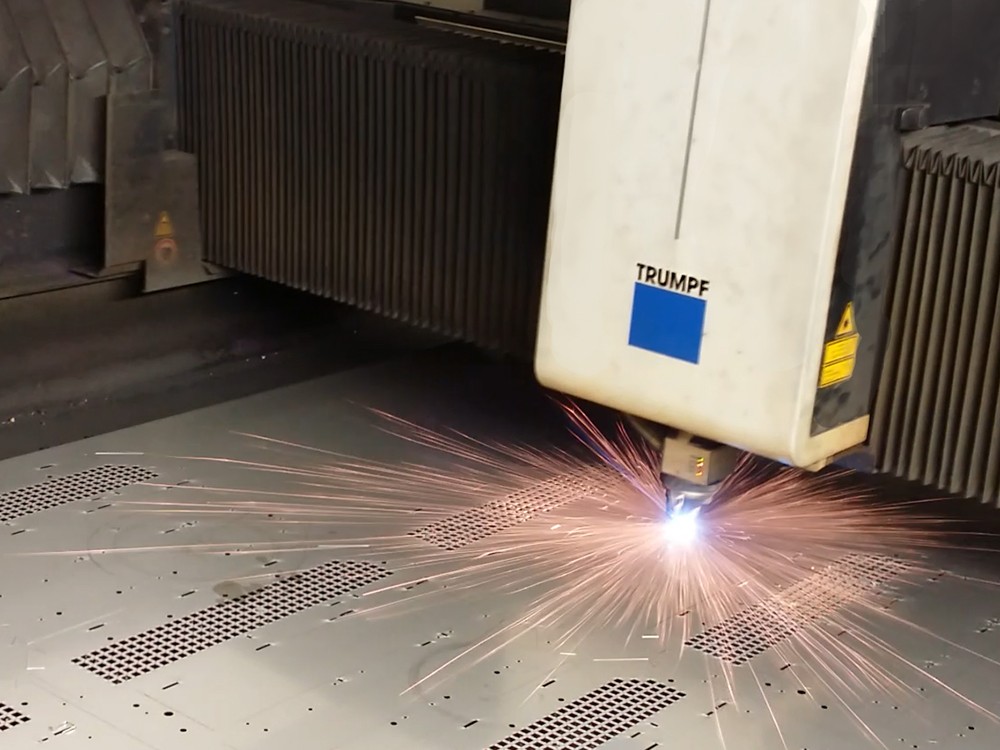

2D laser cutting

2D laser cutting is particularly suitable as a cutting process for components with complex contours. Very narrow kerfs can be achieved and parts can be cut precisely, quickly and without contact. The process has low distortion due to its low heat and energy input.

Compared to conventional manufacturing processes, such as punching or nibbling, laser cutting offers great advantages in terms of cost efficiency, flexibility and scheduling. A wide variety of materials in the thin and thick sheet range can be processed.

It is economical for both small and large quantities. The cutting quality of our laser cutting systems is so good that most of the components we process for you are ready for assembly without reworking.

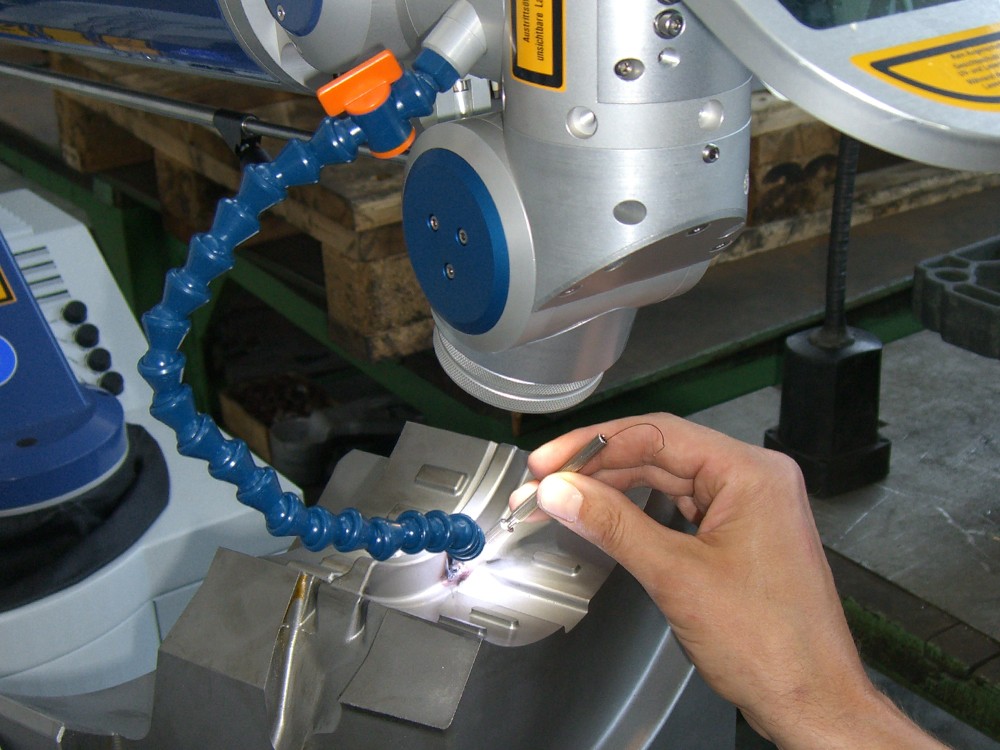

Laser welding

Laser welding is characterized by low heat input and high welding speed. Another advantage of the process is that no filler material is usually used in laser welding. This results in very narrow, even and deep weld seams that are very resilient. The low heat influence during laser welding also makes it possible to join thin-walled components with minimal distortion.

Reworking of the weld seams is rarely necessary with laser welding and complex welding geometries can be realized. Thanks to the advantages of laser welding and the process reliability of the method, we are able to manufacture your components with repeat accuracy and consistently high quality. If required, we can create our own welding fixtures for your components.

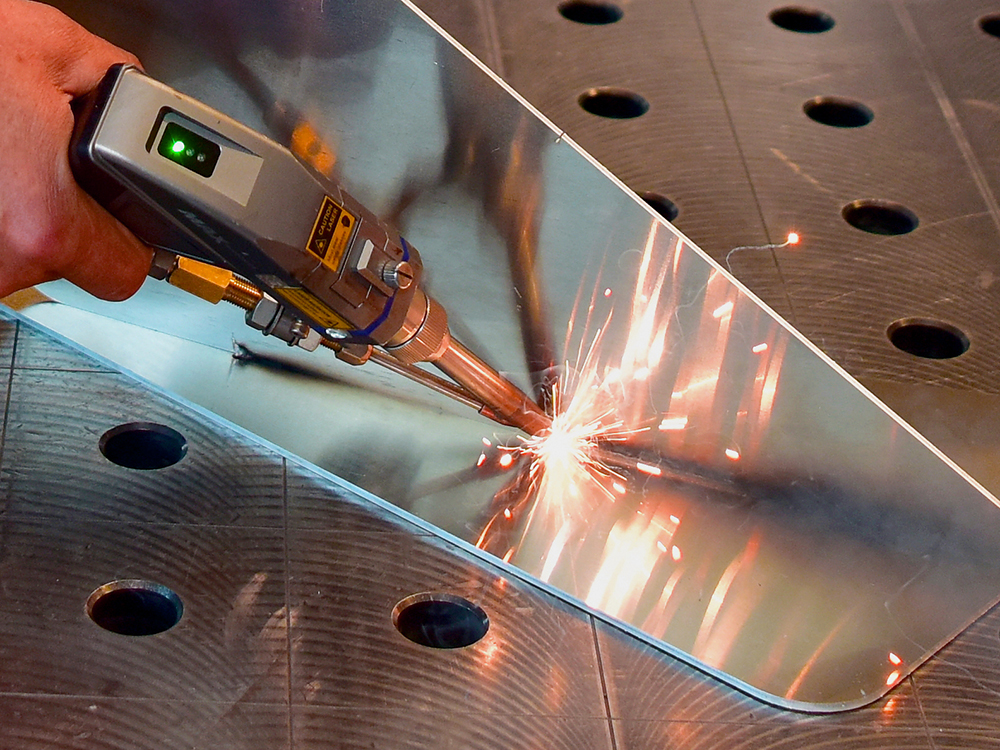

Laser deposition welding

Laser deposition welding is suitable for the fast and economical repair, shape modification or property change of your components. It is characterized in particular by precise and component-friendly processing.

Using a filler wire, material is applied without significantly changing the properties of the base material. The heat-related distortion of the components is minimized by the laser technology. Welding can also be carried out on and in hard-to-reach areas and cavities of the component.

We repair your molds and tools, correct manufacturing and dimensional errors on turned and milled parts and are able to adapt the material properties of your tools, e.g. to enable a longer service life.

We can repair large tools and molds directly on your premises using our mobile laser. The mobile laser is very compact and therefore only requires a small footprint. The laser is self-sufficient except for the power supply. We ensure the safety of your employees in the area of use with suitable shielding.

Your vision, our precision: talk about your project!

Trumpf laser cutting machine TruLaser 5030 fiber

Technical data:

- Tru Disk solid-state laser 5000 Watt

- Double the efficiency of the TruDisk solid-state laser

- Working area: 3000 x 1500 mm

- Up to triple feed rates with the TruDisk solid-state laser

- High productivity and high machine dynamics thanks to direct drives

- Shorter positioning times thanks to simultaneous cutting head positioning

- Mild steel up to t = 25mm; smallest diameter up to 0.35 x material thickness

- Stainless steel up to t = 25mm; smallest diameter up to 0.10 x material thickness

- Aluminum up to t = 25mm; smallest diameter up to 0.20 x material thickness

- Copper up to t = 10mm; smallest diameter up to 0.40 x material thickness

- Brass up to t = 10mm; smallest diameter up to 0.50 x material thickness

Alphalaser ALM 200 mobile

Technical data:

- Dimensions (L x W x H) 1400 mm x 730 mm x 1505 mm

- Total weight approx. 270 kg

- Power consumption 380 V / 50-60 Hz / 3 x 16 A / 8 kW

- 16 A / 8 kW Air-cooled

- Laser crystal: Nd:YAG

- Wavelength 1064 nm